A roof is the most critical part of a house. It protects it from rain, snow, and wind, which can be devastating for your home. A bad roof can also cause leaks that ruin ceilings and floors. If you have a leaky roof, it’s not only going to cost you more money in repairs, but it will also devalue your property if you ever want to sell or rent out the space again.

Mr. Roof is the leading provider of roofing products and services for homeowners. It offers a number of services to help keep your roof in top shape and free of damage. You may prevent significant expenses from roofing damage by working with Mr. Roof for new construction projects, resolving an issue on your present home, or proactively keeping your roof in excellent condition. In order to achieve the best roof possible for your home, the following are some of the best Mr. Roof materials to use on your roofing project:

Shingles

Owens Corning Shingles

Your first choice of materials is to decide on the shingles you want. Shingles from Mr. Roof can withstand the harshest weather conditions and last a long time, making them the perfect choice for any homeowner who wants to protect their investment in their property by choosing high-quality materials that will give them peace of mind with every storm season.

Shingles can be installed in a variety of types and colors to fit your particular design preferences, making it easy to complement the architecture of your house while still getting all of the benefits that shingles offer, including protection against weather extremes like strong winds, hail, heavy snowfall, and more. They also help keep debris out of gutters, which can help prevent the build-up of ice dams.

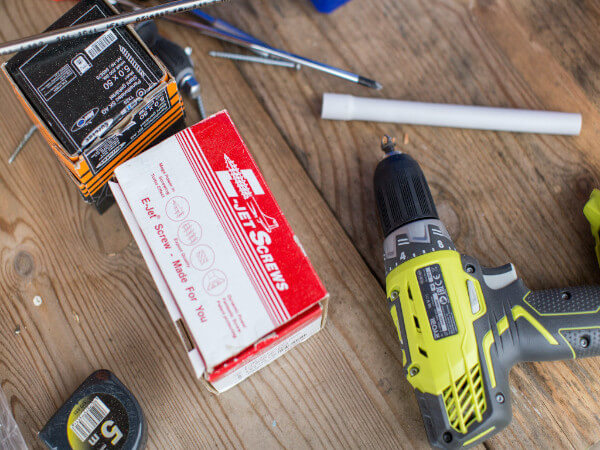

Fasteners

Mr. Roof fasteners are the best for your roofing project because they are guaranteed to be solid and reliable. Mr. Roof uses Trident 3 fasteners, which are specially designed for installations of aluminum and steel roofs. They are also resistant to rust, which is a huge problem when trying to attach a metal roof to a structure that is already rusting. Mr. Roof fasteners have three times the power of a typical smooth shank nail, which means your roof will be secure against any harsh weather.

Underlayment

The next selection you must make is for the underlayment. The underlayment is the material between the shingles and the decking that helps make sure nothing sticks directly to a wooden deck. When you’re building a new home, one of the most important decisions to make is what material you will use for this part of the roof. There are many options out there, but if you want to get it done right the first time, then Mr. Roof underlayment should be your go-to option. Its ThunderShield technology within the underlayment offers excellent coverage because it was specifically designed with longevity in mind, so that even after years of exposure to harsh elements, this product can still do its job without any problems at all.

This material also comes in different types to accommodate the various kinds of roofs that you might have, so it is very versatile and can be tailored to fit your exact requirements. You can also get complete assurance of utmost protection because Mr. Roof’s underlayment is made from the most advanced materials that are both lightweight and durable. That means your roof can last for decades without needing to be replaced.

Ice guard

The ice guard is an essential product that can be used in cold climates to protect your roof from any potential damage caused by water, ice, or snow. It works by sealing all vents and valleys on the roof with a waterproof asphalt membrane that adheres to the roof, keeping it protected against moisture that could cause trouble if ice and snow are allowed to accumulate. Having a roof with a proper ice guard system makes it much easier to keep the snow from getting too heavy and causing structural damage or even the worst-case scenario of a collapse. As one of Mr. Roof’s most popular products for colder climates, this is a great way to keep your home safe and roof up to standard during winter months.

Chimney cap

The chimney cap is the best for your roofing project because it protects the chimney from seasonal elements like leaves, debris, rain, and snow, which could cause significant damage to your roof and living space. The cap also helps prevent animals like birds, squirrels, and raccoons from entering the chimney. If you have a fireplace in your home, then you know how important it is to protect it. A chimney cap will keep all those elements out while allowing smoke to escape through its opening. This prevents smoke buildup inside your home, which poses health risks, among other problems. Many people who invest in a chimney cap are pleased to find that it also enhances the exterior aesthetics of their home. The chimney cap is without a doubt one of the best Mr. Roof materials for your roofing project.

Drip edge

Another type of Mr. Roof material that is great for roofing projects is a drip edge. This type of material helps protect the roof from rain that falls from sloping rooftops. A drip edge is one of the most effective ways to protect a home’s structure, and it helps cut down on the amount of water damage to a home’s interior. A drip edge can be installed quickly and does not require any special tools or skills.

A prefabricated metal sloped surface typically works well as a drip edge because it can be easily attached without having to use any masonry adhesive or mortar. A prefabricated metal surface like this will also help with the durability and longevity of the roof.

Once a drip edge has been installed, it is important to take care of this material so that it will continue to protect the roof. This means that homeowners need to keep gutters clean and clear of debris, which will help water make its way away from the roof and down to the ground. This is important because debris can damage a drip edge as well as other types of roof materials.

Homeowners should also avoid using any harsh cleaning chemicals, which can strip the protective coating off a drip edge and cause it to rust. One of the best ways to clean a drip edge is by using a simple garden hose and warm water, which will help keep it in good condition and functioning correctly.

Taking good care of a drip edge will help maintain the integrity of a roofing project as well as protect it from damage.

Sealant

Sealant is hands down one of the best Mr. Roof materials for your project. Liquid sealants are used to make surfaces waterproof and airtight. They can be applied to seams, windows, doors, tanks, and of course, roofs.

The most common types of sealants are asphalt-based and silicone-based. Asphalt-based products can be adhesive or non-adhesive, while silicone-based products usually have an adhesive quality to them that makes them easier to install in hard-to-reach places around a roof. In order for a sealant to work effectively, it must conform perfectly with the surface you’re applying it on. This task can be extremely tricky, which is why contacting a roofing company like Mr. Roof to install a professional quality sealant instead of trying it yourself can save you a lot of time and energy while ensuring a top-quality installation.

Roof vent

When it’s hot outside, the air gets warm and wants to go up. It then flows into your house and makes it hotter. While problematic, you can stop the air from getting in with a roof vent. With a roof vent, the air can’t get in because there is a cover on top of the vent, forcing the airflow to go somewhere else.

The best Mr. Roof materials for your roofing project are the ones that will make it last as long as possible and still look good. Hands down, this is a roof vent. This should be installed straight away to keep your home cool in summer and warm in winter. At Mr. Roof, we can supply you with vents that won’t let water creep into your house or rot your wooden ceiling boards. The roof vent is the first line of defense for your roof and should be considered as important as anything else on it.

Connect with Mr. Roof today

As you can see, there are many types of Mr. Roof materials that can be installed as part of your roofing project. These high-quality, durable materials can help protect your home for years to come. If you’re interested in learning more about the best Mr. Roof materials or how they can be installed, contact Mr. Roof today to learn more and begin your roofing project with the best materials available on the market.

The post The Best Mr. Roof Materials for Your Roofing Project appeared first on Mr Roof.