A new report estimates that one-fourth of all critical infrastructure in the U.S. is at risk of flooding, and that percentage will increase as storms become more severe due to climate change.

The science and technology nonprofit First Street Foundation, in what it calls “the first ever nationwide community level flood resilience report,” says state and local governments are not equipped to handle the present and future flood risks to critical infrastructure.

“As we saw following the devastation of Hurricane Ida, our nation’s infrastructure is not built to a standard that protects against the level of flood risk we face today, let alone how those risks will grow over the next 30 years as the climate changes,” says Matthew Eby, founder and executive director of First Street Foundation.

The “Infrastructure on the Brink” report says that 25% of current “critical infrastructure,” such as utilities, airports, ports, and emergency services like police, fire and hospitals, is at risk of becoming inoperable due to flooding.

It estimates these other current infrastructure flood risks:

23% of all road segments in the country (nearly 2 million miles of road). 20% of all commercial properties (919,000).17% of all “social infrastructure” facilities (72,000). This includes such properties as schools and government buildings.14% of all residential properties (12.4 million).

The risks are expected to increase through 2051.

“Over the next 30 years, due to the impacts of climate change, an additional 1.2 million residential properties, 66,000 commercial properties, 63,000 miles of roads, 6,100 pieces of social infrastructure and 2,000 pieces of critical infrastructure will also have flood risk that would render them inoperable, inaccessible or impassable,” the report says.

This chart shows the expected increase in flood risks by infrastructure category over the next 30 years.First Street Foundation’s “Infrastructure on the Brink” report

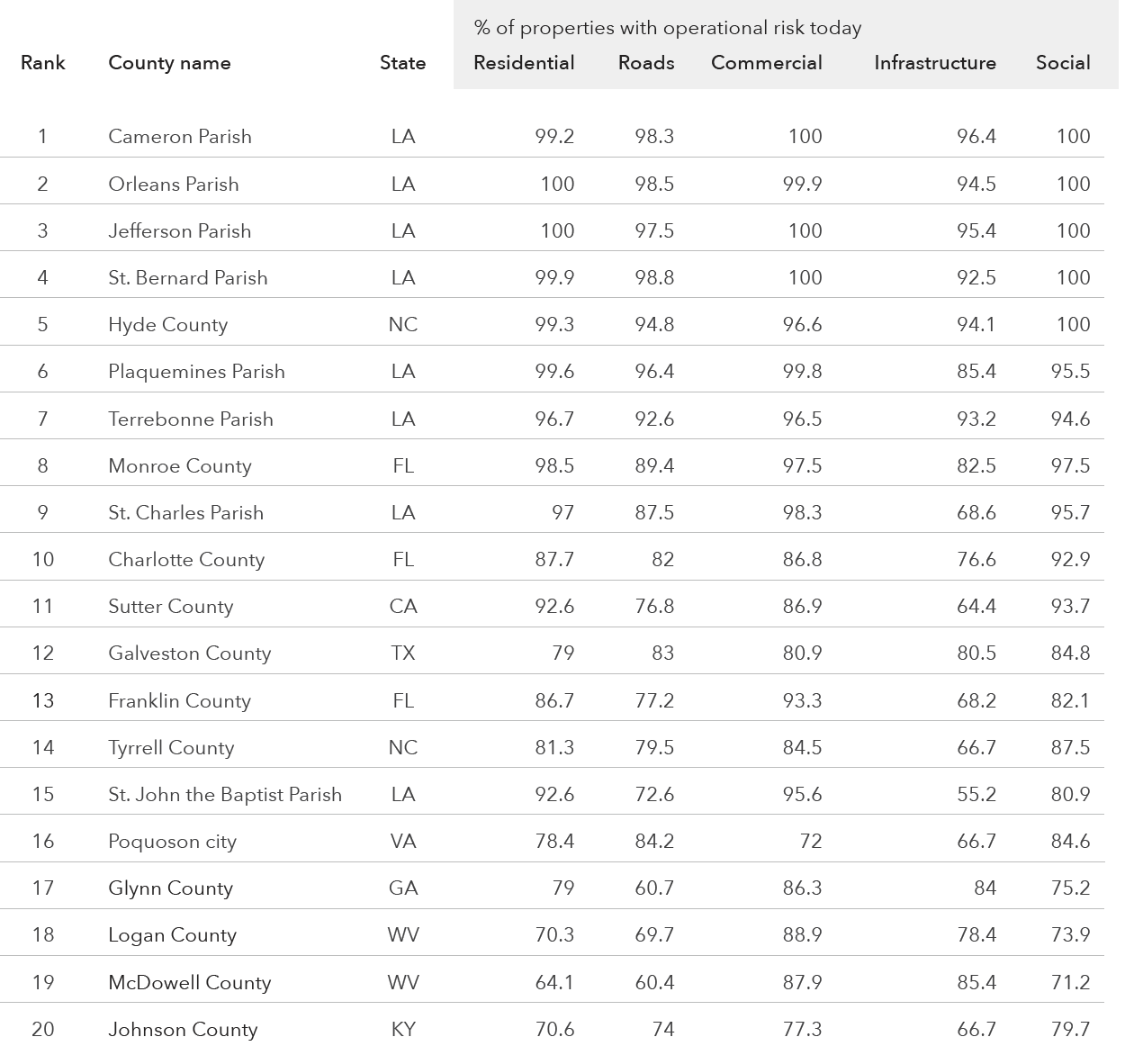

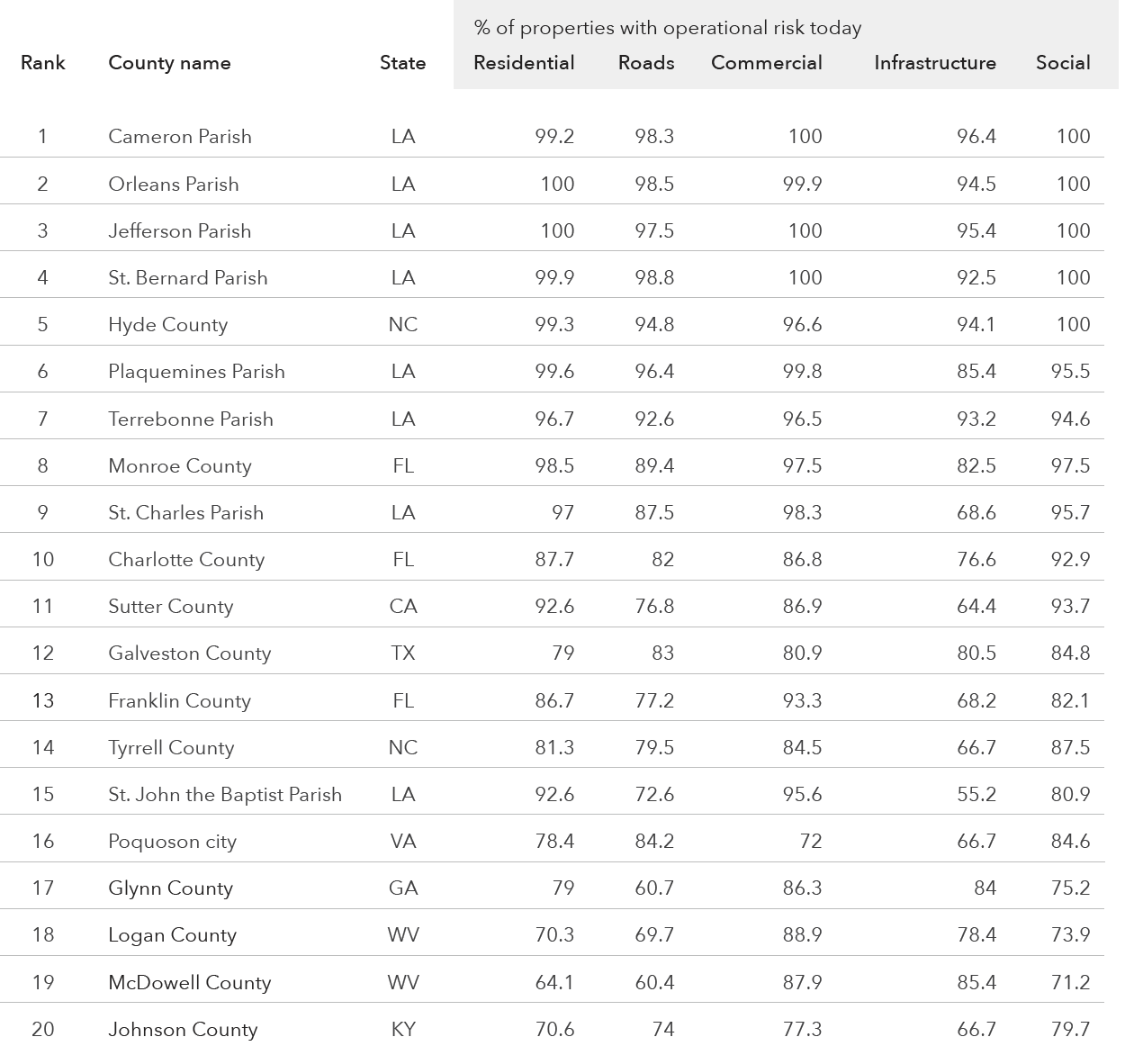

The report shows these four states facing the highest concentration of current risk: Louisiana, Florida, Kentucky and West Virginia. Of the top-20 at-risk counties in the U.S., 17 are in these four states.

The report also provides data on all at-risk cities and counties, and you can search on First Street’s website to find the flood risk for your property with the nonprofit’s free FloodFactor tool.

This chart shows the top-20 counties most at-risk to physical infrastructure flooding and the percentages of their infrastructure categories that are at risk. (Note: The “Infrastructure” column represents “critical infrastructure,” such as airports, fire stations, hospitals, police stations, ports, power stations.)First Street Foundation’s “Infrastructure on the Brink” report

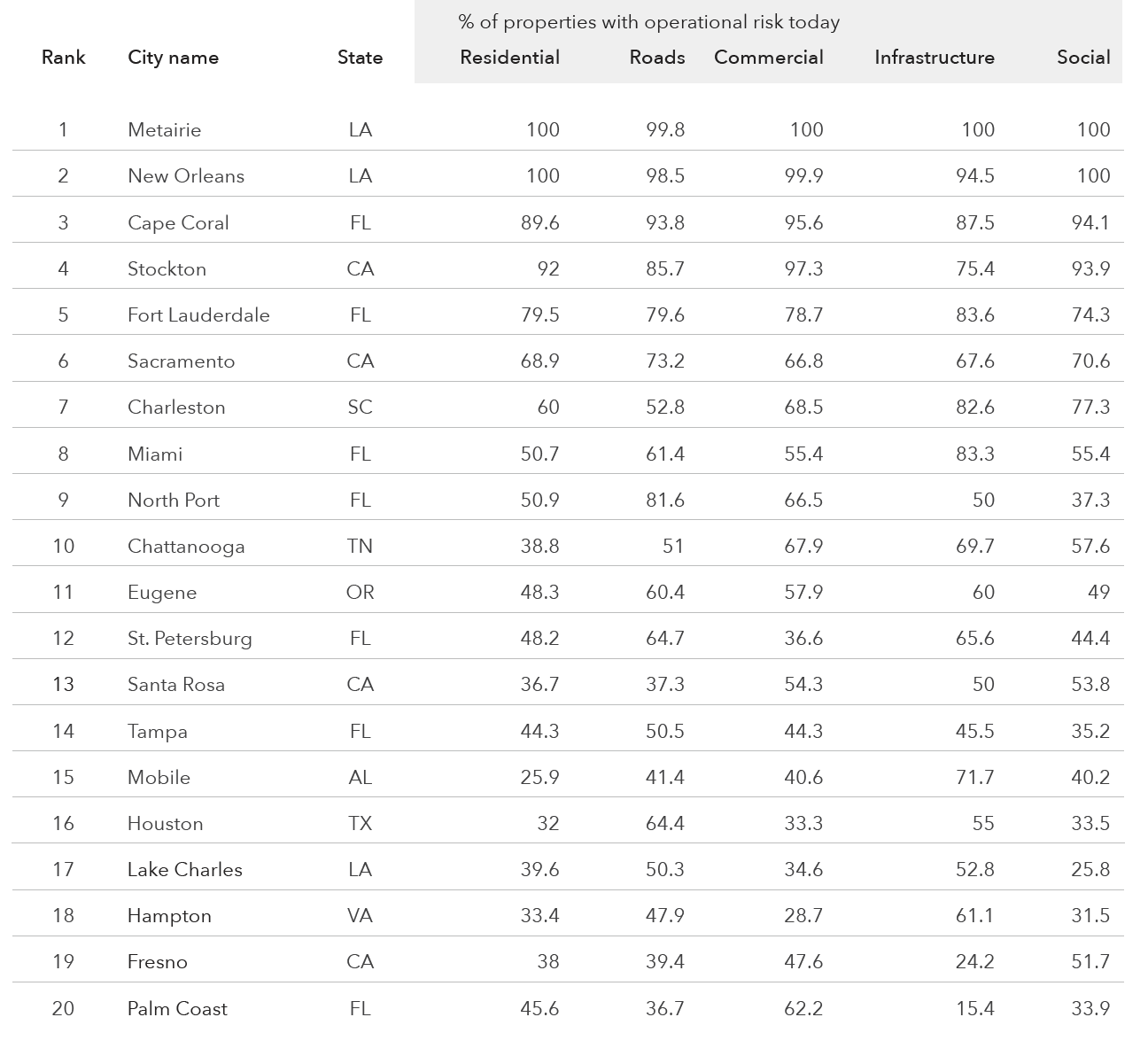

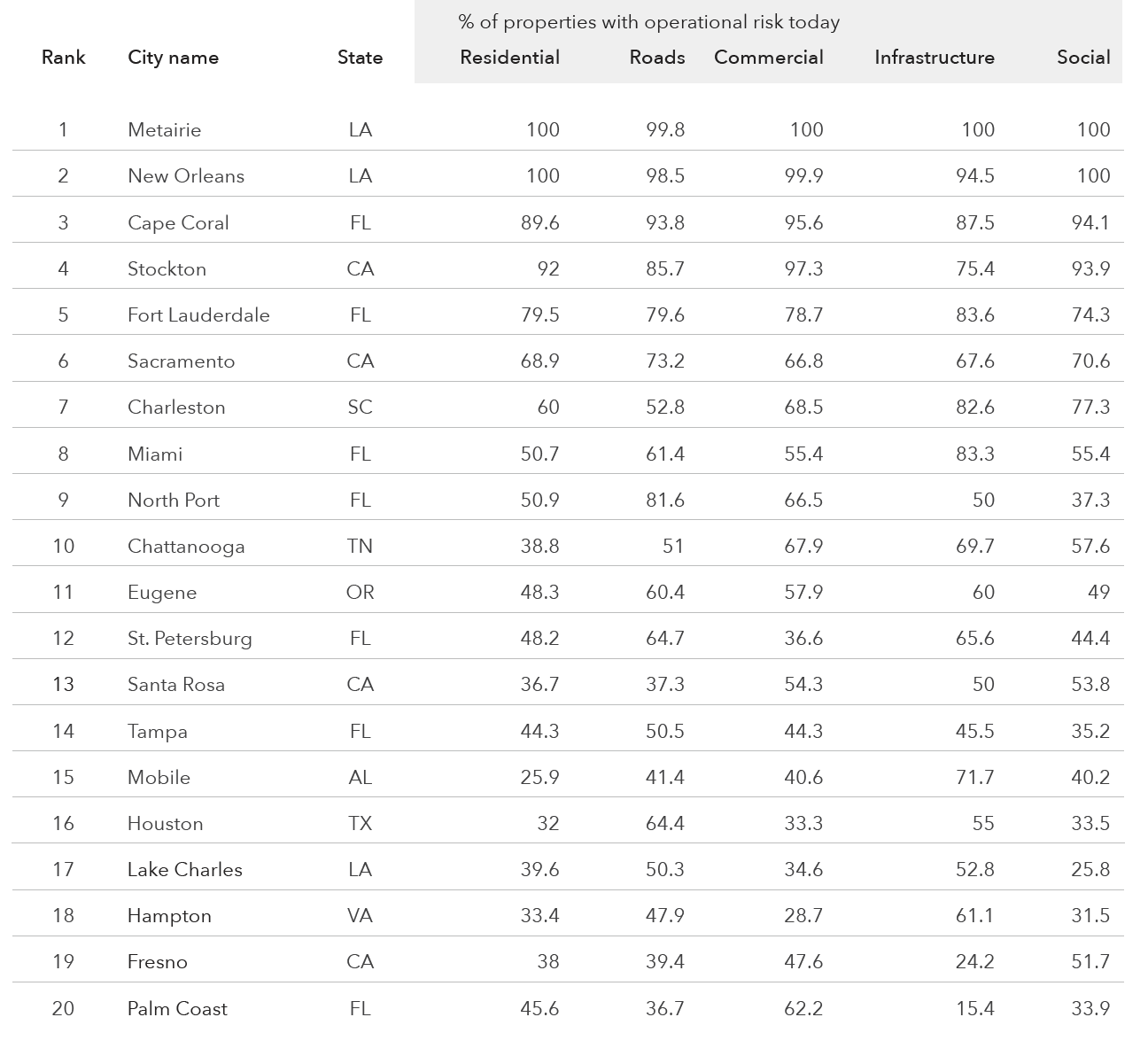

For cities facing the most flood risk today, Moliere and New Orleans, Louisiana, top the rankings, with most, if not all, of their infrastructure vulnerable. Cities in California, South Carolina, Florida and Alabama also made the list.

This chart shows the top-20 cities most at-risk to physical infrastructure flooding and the percentages of their infrastructure categories that are at risk. (Note: The “Infrastructure” column represents “critical infrastructure,” such as airports, fire stations, hospitals, police stations, ports, power stations.)First Street Foundation’s “Infrastructure on the Brink” report

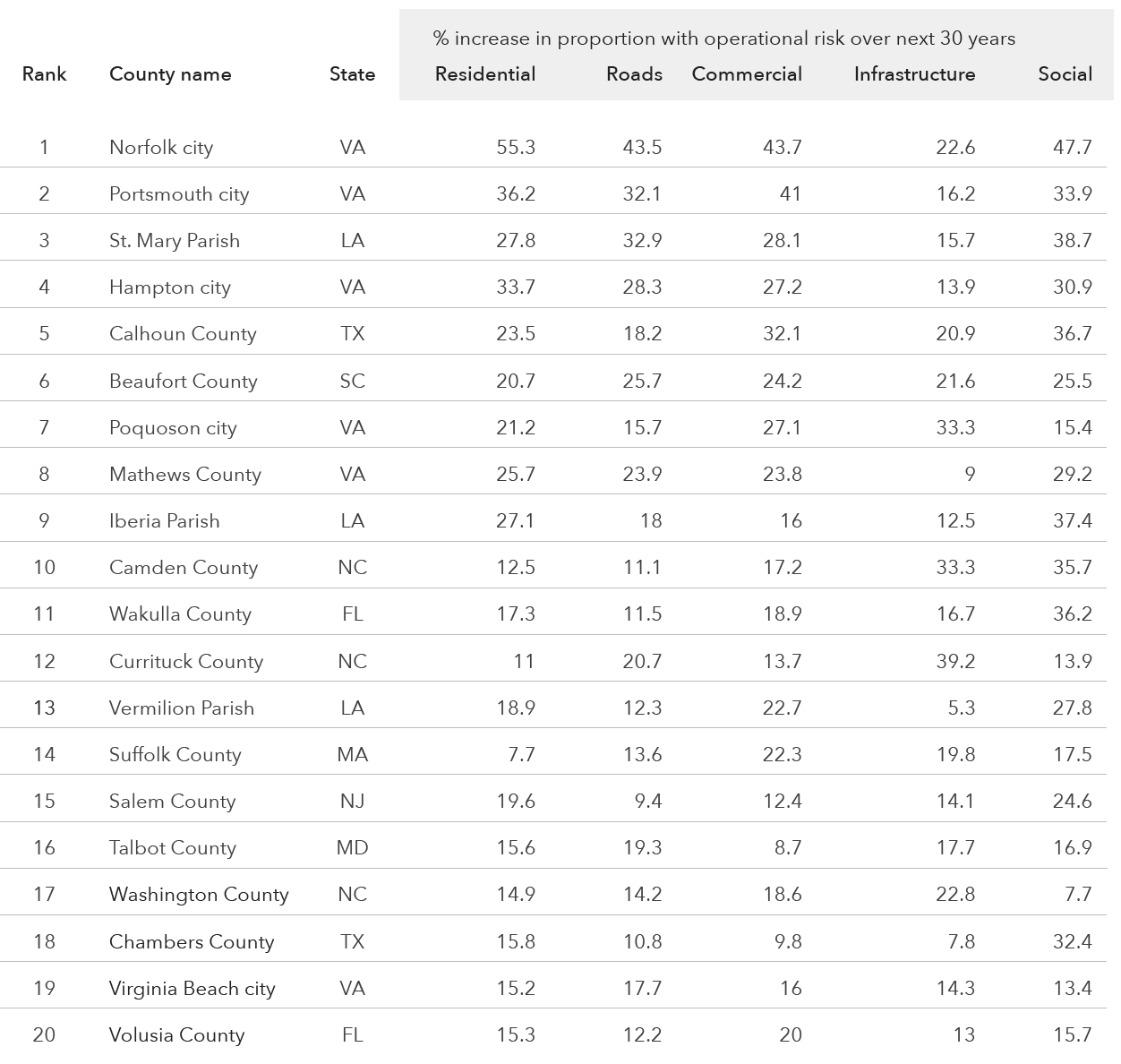

The report also looks into the future, showing which counties will see the largest percentage increase in infrastructure risk by 2051. Virginia has several metro areas facing a significantly increased threat. The list also includes counties in North Carolina, Massachusetts, Maryland and Texas.

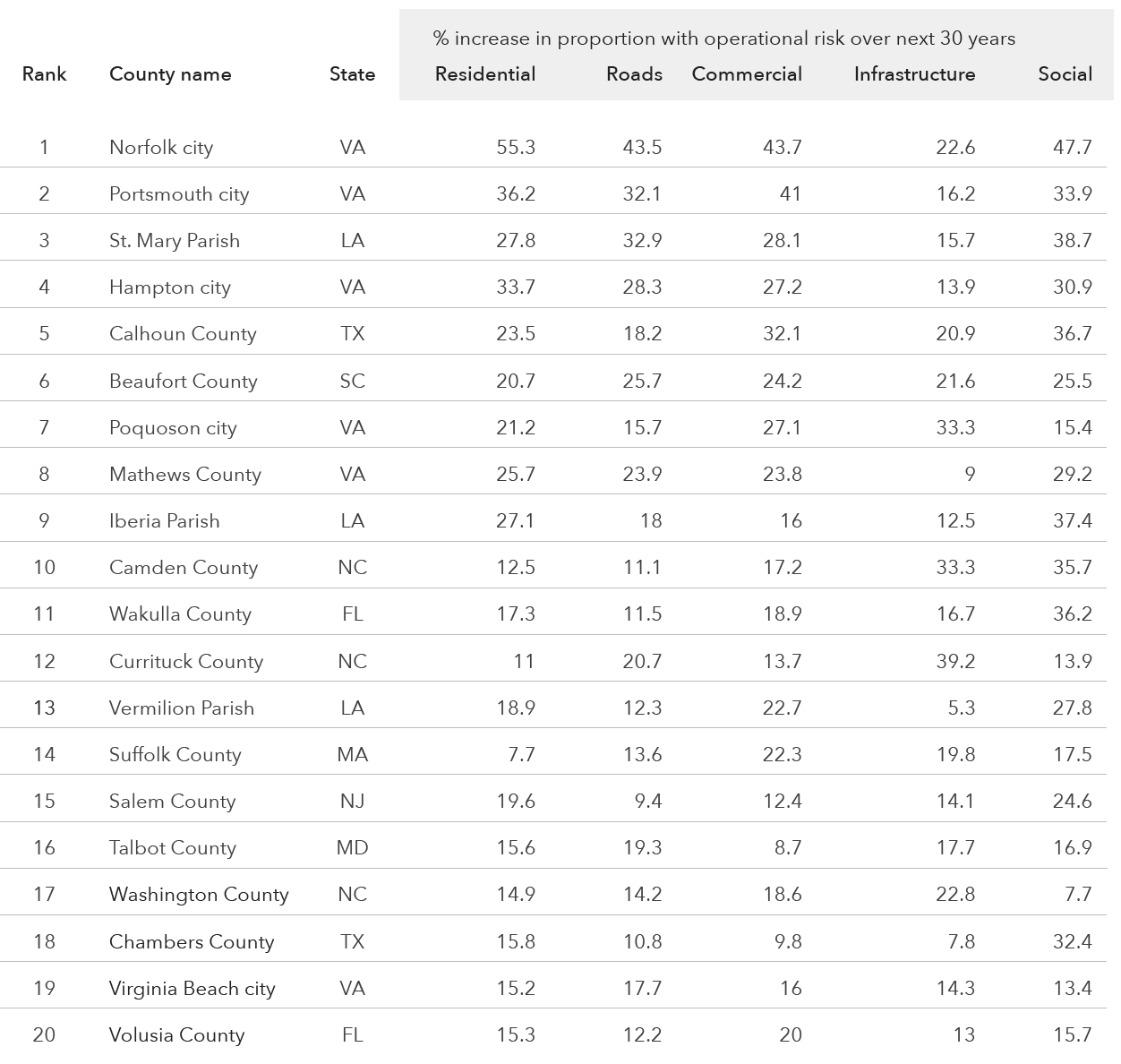

This chart shows the top-20 counties with the highest estimated percentage increase of risk to physical infrastructure flooding by 2051 and the percentages of their infrastructure categories that are at risk. (Note: The “Infrastructure” column represents “critical infrastructure,” such as airports, fire stations, hospitals, police stations, ports, power stations.)First Street Foundation’s “Infrastructure on the Brink” report

The report says the impact of the increased risks could devastate local communities. It notes that in Harris County, Texas, home to Houston, 770 hospitals, public utilities and water-treatment plants currently risk becoming inoperable due to flooding this year.

Miami-Dade, Florida, has 1,640 schools, churches and museums at risk. The Chicago metro area has 225,000 residential properties at risk. And in the New Orleans area, 99% of the roads are at risk of becoming undrivable because of flooding, the report says.

First Street Foundation hopes the data will help prioritize funding toward protecting infrastructure from flood risks.

“Our work aims to determine the amount of flooding that would render infrastructure either inoperable or inaccessible,” says Dr. Jeremy Porter of First Street Foundation. “By applying research on depth thresholds and comparing them to flood data and probability metrics, we can determine roughly the extent of flooding that would cause a road to be impassable to cars, or a hospital to be shut down.”

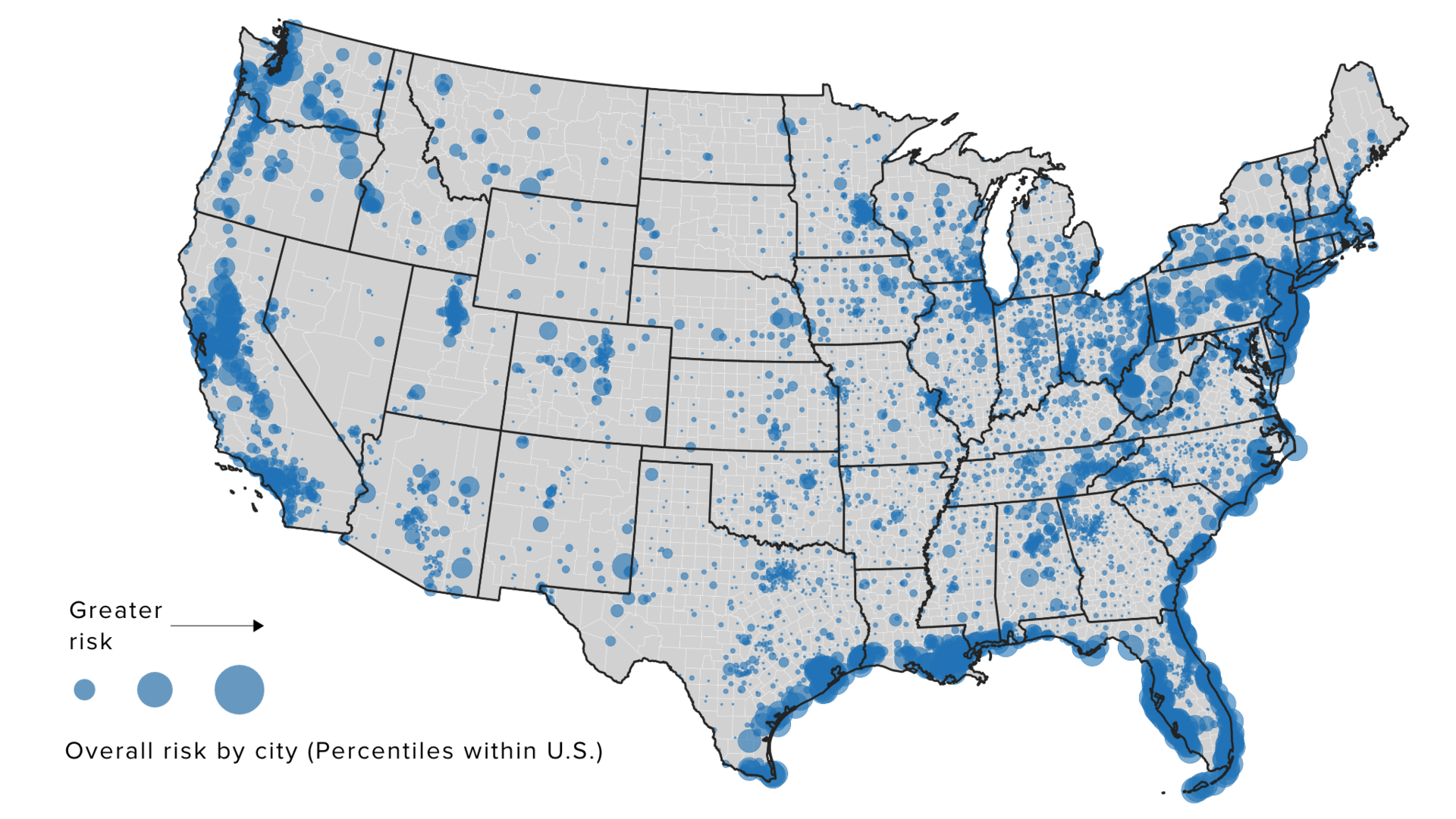

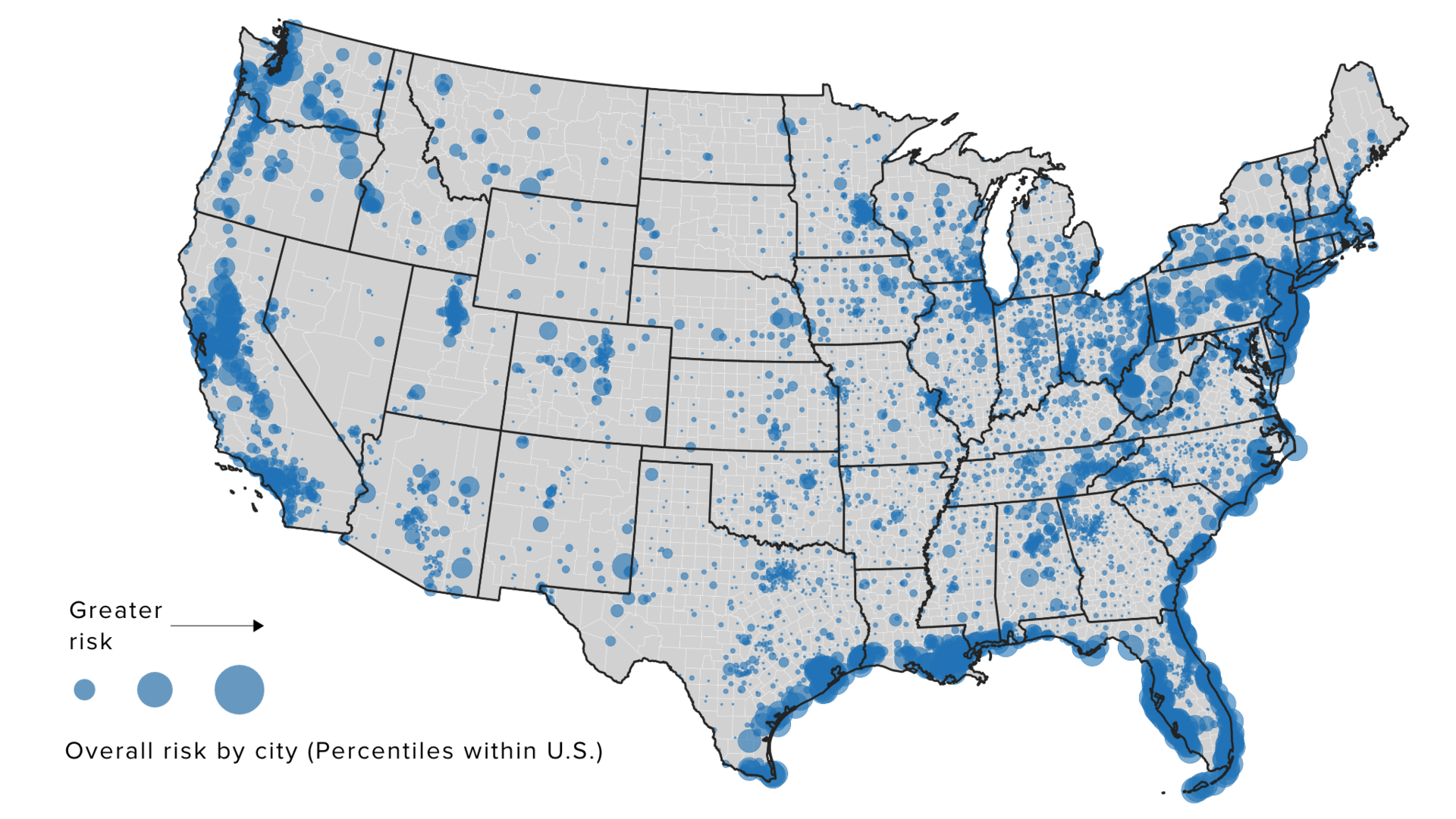

This map shows where the greatest flood risks are to infrastructure.First Street Foundation’s “Infrastructure on the Brink” report