Replacing your windows is one of the simplest yet most significant renovations you can make to improve your home’s appearance, functionality, and value. In its2019 Remodeling Impact Report, the National Association of Realtors Research Group found that American families spend approximately $400 billion each year on home renovation projects, a sizable portion of which is dedicated to window replacement. New vinyl windows rank as the second-highest, most appealing exterior renovation project for homeowners, and the second-highest exterior project most likely to add property value when the home is listed for resale in the future.

If you are interested in upgrading your windows, you must understand the anatomy of a window to select the right product for your home. Window manufacturers, installers, and contractors implement various industry-specific terms that you should be familiar with, so you are fully informed and prepared to discuss your window replacement project. Consult the information below to learn more about the anatomy of windows and how new windows can improve your home value, save you on energy bills, and help protect the environment. After you review this resource, contactMr. Roof to speak with our team about our product offerings.

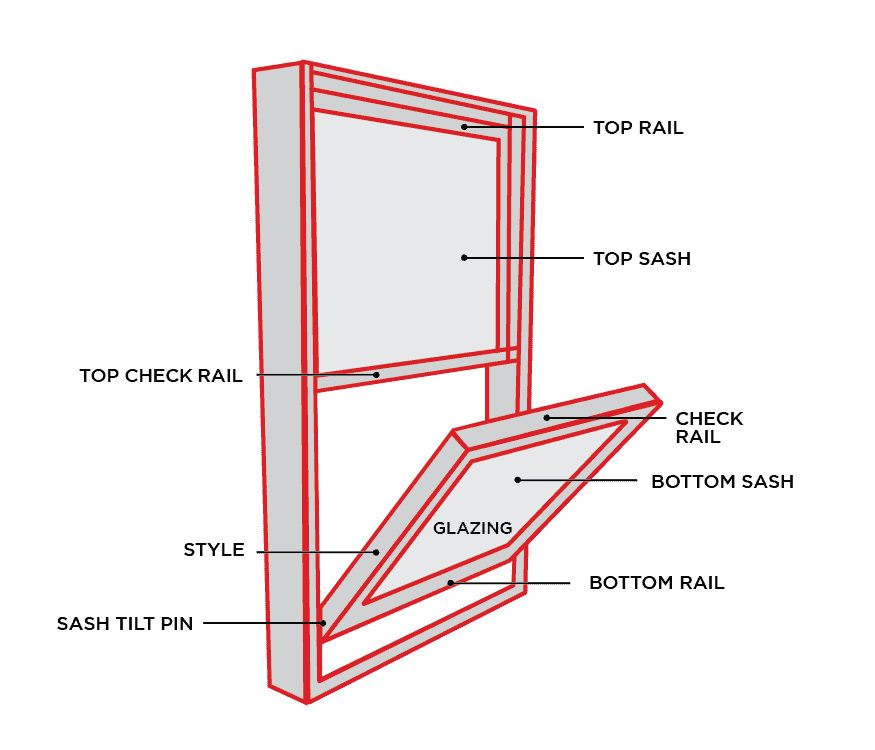

Exterior anatomy of a window

A window’s exterior anatomy consists of the following parts:

Frame. The frame surrounds the window and provides structural support for the entire window system. It is constructed of a head, jam, and sill.Head. The head consists of the main horizontal component that forms the top of the window frame.Jambs. The side jambs are the main vertical components that form the sides of the window frame, and the head jamb is the horizontal component at the top.Sill. The sill is the main horizontal component that forms the bottom of the window frame. It features a tapered shape on the exterior to shed excess water.Jamb liner. The jamb liner is a strip installed on either side of a window frame to cover the space between the frame and the interior wall. It is generally made of wood and may be installed during the manufacturing process or on site when the windows are replaced. In some cases, plaster or drywall can be applied to the frame to remove the need for a jamb liner.

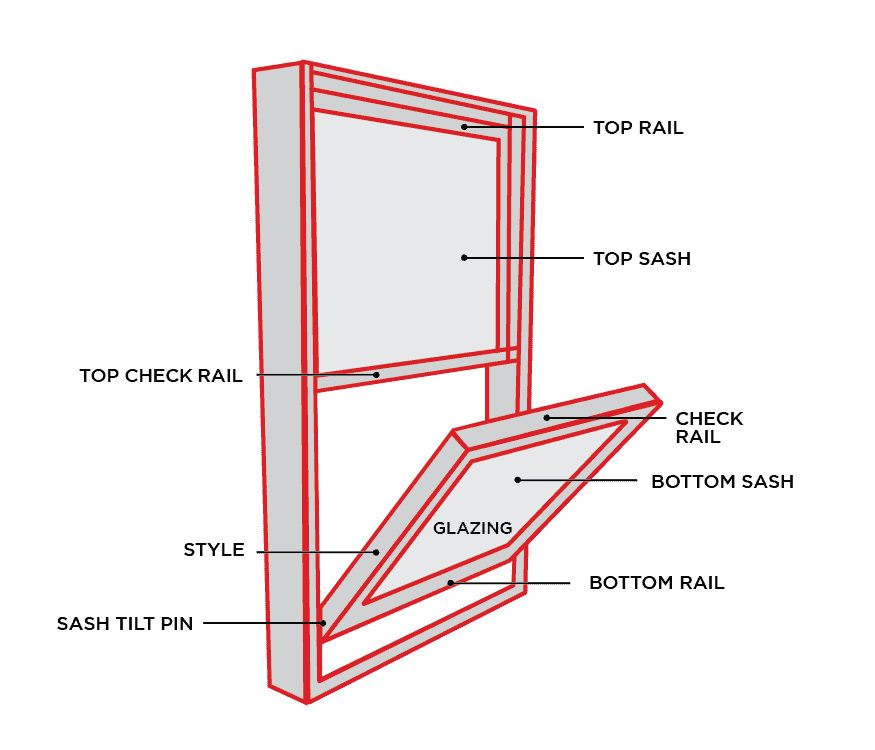

Interior anatomy of a window

A window’s interior anatomy consists of the following parts:

Sash. The sash is the operable component of the window that fits inside the frame and holds the window glass in place. It can be made of several materials, including wood, vinyl, fiberglass, aluminum, or composite. A double-hung window has two sashes that can move up and down and tilt inward. A sliding window has one sash that moves from left to right, and a casement window has one sash that is operated using a handle.Top sash. The top sash is the upper sash on a double-hung window.Bottom sash. The bottom sash is the lower sash on a double-hung window.Stile. Stiles are the vertical parts of the sash.Rail. Rails are the horizontal parts of the sash.Check rail. Check rails are where the frames of individual glass panes meet. On a double-hung window, the check rails meet in the middle of the window or the horizontal point of contact between the bottom of the top sash (top check rail) and the top of the bottom cash (bottom check rail). On a sliding window, the check rails are found at the meeting point of the two vertical panes of glass.Top rail. The top rail, or upper rail, is the top part of the top sash.Bottom rail. The bottom rail, or lower rail, is the lower part of the lower sash.Glazing. Glazing refers to the sheet of glass located within the window frame. Traditional windows featured one layer of glass, while modern windows typically include two or three layers of glass with inert gas injected between them for additional insulation. Invisible coatings can be added to glazing to manage the light and heat that passes through a window or reflects away from it. Tinted or laminated glazing can add privacy and enhance strength.Lift. A lift is a handle found on a wooden single-hung or double-hung window that raises the lower sash.Sash tilt pin. The sash tilt pin consists of a mechanism that allows sashes to tilt inwards for cleaning the exterior of the panes from the inside of the home.Sash lock. The sash lock comprises a locking mechanism that engages the lock strike of a single-hung or double-hung window to decrease rattling.Balances. Window balances are mechanisms found within the jambs on either side of a single-hung or double-hung window that counterbalance the sashes, so they are easier to open and do not slam shut. They were originally constructed of systems with a lead weight and pulley but now feature block and tackle systems that supply tension with strings.Operating handle. The operating handle is the mechanism on casement or awning windows that open and close the sash along with the operating arm. A crank operating handle extends the operating arm and opens the sash when turned in one direction and retracts the arm, and closes the sash when turned in the other direction. Some windows have non-crank handles that open and close the sashes by manually pushing them.Operating arm. The operating arm is the mechanism on casement, awning, or hopper windows that works with the operating handle to open and close the sash or hold it in position when it’s open.Locking handle. The locking handle consists of a handle- or lever-operated lock that pulls the sashes together to improve energy efficiency and security.

Improve your home with new windows

In the 2019 Remodeling Impact report mentioned above, 42% of survey respondents stated that their window replacement added functionality and livability to their home. After completing their project, 80% of homeowners feel a sense of accomplishment, 64% report a greater desire to spend time at home, and 63% experience increased enjoyment of their home. The average cost of a vinyl window replacement equals around $22,500, and homeowners recovered an estimated $16,000 for this project. This impressive 71% return on investment makes window replacement one of the best and most sought-after renovation projects for homeowners across the country.

Save money with new windows

Compared to all other home improvement projects, a vinyl window replacement consistently ranks as the most efficient use of your renovation budget. They offer a significant three-fold return by increasing the value, energy efficiency, and curb appeal of your home. Replacing your outdated windows with modern energy-efficient models allows you to significantly lower your heating and cooling expenses while improving the exterior appearance of your home. According to Energy Star, you can save 12% of your annual energy bills with new windows. Homeowners can expect to save up to $197 per year with double-pane window replacements or up to $583 per year with single-pane replacements.

Protect the environment with new windows

Not only do new windows add value to your property and save you money, but they also help protect the environment by reducing your carbon footprint. Your carbon footprint refers to the amount of carbon dioxide emissions that result from your daily activities, such as turning on a light, driving a car, or purchasing a product. A full quarter of your carbon footprint consists of your home energy usage, so the energy savings from replacing your windows can reduce your family’s carbon footprint for decades. A single-pane window replacement saves 246-2,001 pounds of carbon dioxide annually or the equivalent of 13-102 gallons of gasoline. A double-pane window replacement saves 1,006-6,205 pounds of carbon dioxide or the equivalent of 51 to 317 gallons of gasoline.

Contact Mr. Roof today

For the highest quality window replacements at the most affordable prices, contact Mr. Roof today. With half a century of experience, our roof and exterior service company has become widely respected for our quality products, skilled craftsmanship, and exceptional customer service. Our expert team of fully licensed, bonded, and insured window installers uses the most reliable and innovative solutions available, including:

Low E argon-filled glass traps heat during the winter and reflects it during the summer.Scratch-resistant glass maintains its new appearance for far longer than normal glass.Fusion welding produces airtight, waterproof, permanently sealed seams.Reinforced interlock to reduce air intrusion and enhance security.5-layer weather-strip forms a barrier against wind, sound, dust, and insects.Repel technology resists rain, snow, and sleet.

We will custom create your replacement windows based on your home’s needs and fully insulate, trim, and seal them from the inside out. In 98% of cases, we can complete a window replacement in one day, from delivery of materials to cleanup at the end of the project. We offer a lifetime warranty for all materials and a lifetime warranty for labor covering the entire length of time you reside in your home.

Contact us today for an initial consultation by submitting the form on our website. We will visit your home to take measurements, explain your options, provide a cost estimate, and display a 3D visualization of your project, so you know exactly what to expect.

The post Anatomy of a Window appeared first on Mr Roof.